Mask machine/Full automatic bottle blowing machine/Blow mould/Cap mould

Mask machine/Full automatic bottle blowing machine/Blow mould/Cap mould

is located in the TAIZHOU,which is the developed economy city of CHINA.We set foot in the blow molding machine and moul area since 1996.Uphold domestic and foreign advanced technology and ideas,It has become a design,manufacture,sales and service comprehensive enterprise.

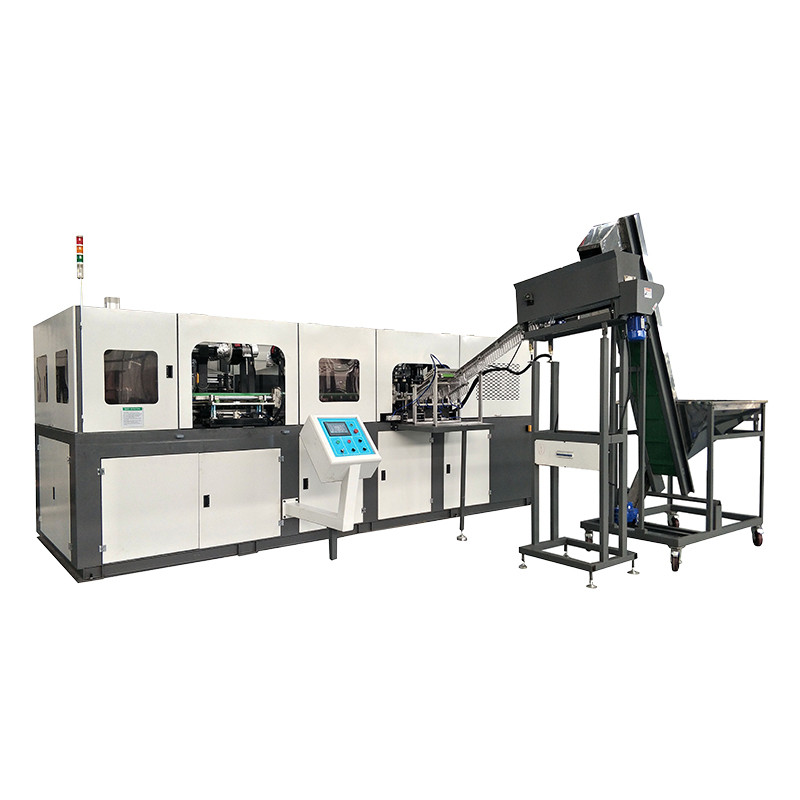

- Full automatic bottle blowing machine

- Semi automatic bottle blowing machine

- Blow mould

- Bottle mould

- Injection machine

-

-

Custom-made Full automatic bottle blowing machine Category: [Full automatic bottle blowing machine]

$0.00$0.00

-

-

HY-5G Full automatic bottle blowing machine Category: [Full automatic bottle blowing machine]

$0.00$0.00

-

-

HY-5L Full automatic bottle blowing machine Category: [Full automatic bottle blowing machine]

$0.00$0.00

-

-

HY-6000 Full automatic bottle blowing machine Category: [Full automatic bottle blowing machine]

$0.00$0.00

-

-

HY-B-II Semi automatic bottle blowing machine Category: [Semi automatic bottle blowing machine]

$0.00$0.00

-

-

HY-B-I Semi automatic bottle blowing machine Category: [Semi automatic bottle blowing machine]

$0.00$0.00

-

-

HY-B3 Semi automatic bottle blowing machine Category: [Semi automatic bottle blowing machine]

$0.00$0.00

-

-

HY-B4 Semi automatic bottle blowing machine Category: [Semi automatic bottle blowing machine]

$0.00$0.00

-

-

Blow mould 1 Category: [Blow mould]

$0.00$0.00

-

-

Blow mould 2 Category: [Blow mould]

$0.00$0.00

-

-

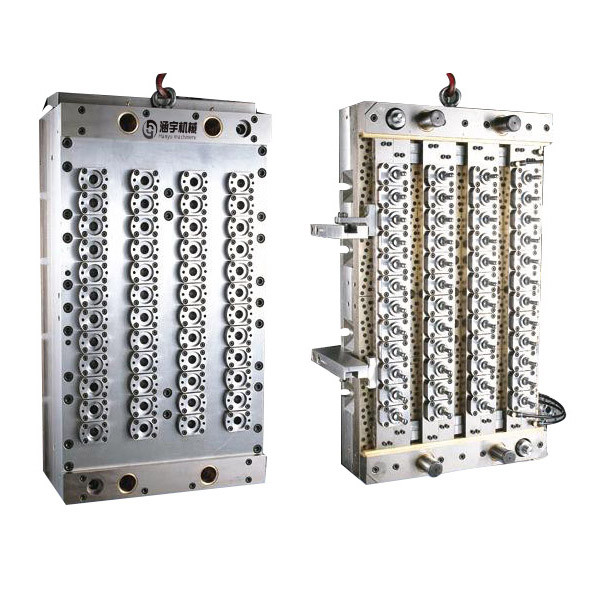

48 cavity pneumatic needle valve type hot runner mould Category: [Bottle mould]

$0.00$0.00

-

-

32 cavity pneumatic needle valve type hot runner mould Category: [Bottle mould]

$0.00$0.00

-

-

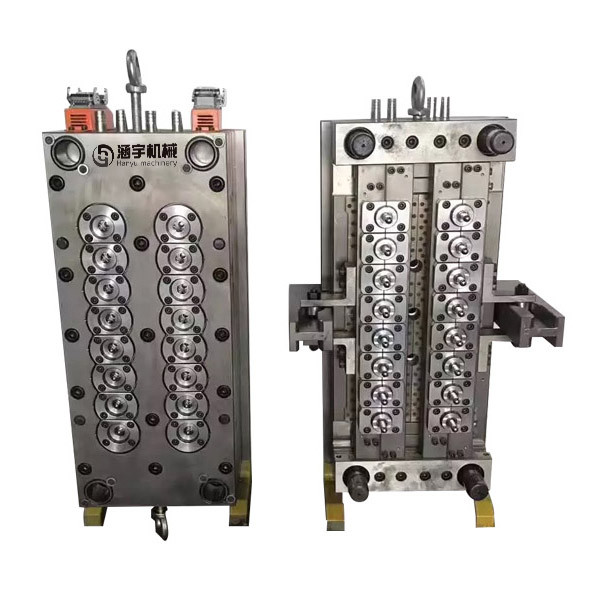

24 cavity pneumatic needle valve type hot runner mould Category: [Bottle mould]

$0.00$0.00

-

-

16 cavity pneumatic needle valve type hot runner mould Category: [Bottle mould]

$0.00$0.00

-

-

PET Injection machine Category: [Injection machine]

$0.00$0.00PET Servo Injection Machine注射装置Injection Unit单位

unit

SV118 PET SV140 PET SV190 PET SV220 PET SV270 PET SV300 PET SV330 PET SV380-PET SV450-PET SV530-PET SV650 PET 螺杆直径Screw Diametermm 36 40 40 45 45 50 50 55 55 60 60 65 65 70 70 75 75 80 85 90 90 100 长径比Screw L/D RatioL/D 24.5 24.8 24.9 24.6 24.6 24.5 24.8 24.7 24.3 24.3 24.3 24 24.9 24.6 25 24.7 24.6 24.4 24.8 24.6 24.2 24.3 理论注射容积Shot Volumcm³ 188 232 253 321 395 488 512 620 688 819 805 945 1098 1274 1374 1577 1723 1960 2614 2931 2818 3479 注射重量Injection Weight(PET)g 225 278 303 385 474 585 614 744 825 982 966 1134 1317 1528 1648 1892 2067 2352 3136 3517 3381 4174 注射压力Injection PressureMpa

160 129 164 130 154 125 155 128 148 124 154 131 159 137 157 136 155 136 139 124 154 125 注射速率Injection Ratecm³/s 94.5 116.7 107.5 136 150.6 186 189.2 228.9 252 300 293 344 322 373 386 443 480 547 602 675 678 836 注射速度Injection Speedmm/s 93 90 95 96 106 107 97 100 108 110 106 塑化能力Plasticizing Capacityg/s 15.6 21.5 21.5 29.3 25.4 33.1 35.1 38.7 43.7 49 56.5 70 64.4 78.8 83.4 86.5 99.7 108.6 144 169 140 182 螺杆转速Screw Speedrpm 0-190 0-190 0-165 0-175 0-155 0-175 0-160 0-180 0-170 0-180 0-155 0-180 0-160 0-175 0-138 合模装置Clamping Unit合模力Clamp TonnageKN 1180 1300 1700 2200 2700 2980 3300 3800 4500 5300 6500 移模行程Toggle Strokemm 330 360 430 490 545 590 660 670 760 850 900 拉杆内距Space Between Tie-Barsmm 375x375 420x420 470x470 530x530 580x580 615x615 685x685 730x710 760x760 840x830 910x910 最大模厚Max. Mold Heightmm 430 450 520 550 580 630 670 720 800 850 900 最小模厚Min. Mold Heightmm 150 150 180 200 220 200 270 250 300 350 400 顶出行程Eiector Strokemm 100 120 140 140 150 150 170 170 200 220 260 顶出力Ejector TonnageKN 33 33 39 62 62 80 90 110 110 158 175 顶出杆数Ejector NumberPiece 5 5 5 9 9 9 13 13 13 13 17 其他 Others 最大油泵压力Max. Pump PressureMpa 14 14 14 14 14 14 14 14 14 14 14 电机功率Motor PowerKW 8.9 13 18 22 26 34 34 36 22+34 22+36 34+36 电热功率Heater PowerKW 8.65 12.2 13.85 20.25 23.05 22.5 31.05 32.65 38.9 55 53.5 外形尺寸Machine Dimensionm 4.5x1.2x1.8 4.95x1.25x1.85 5.61x1.3x2.1 6x1.4x2.1 6.1x1.48x2.2 6.3x1.55x2.35 7.2x1.76x2.4 7.4x1.8x2.5 8.25x2x2.55 9.1x2x2.5 10.5x2.2x2.8 机器重量Machine WeightT 3.5 4 5.6 6.8 9 9 13.5 15.5 18 22.5 36 油箱容积Oil Tank CapacityL 250 280 350 450 600 700 850 950 1000 1100 1550

- Industry information

- Company news

-

-

[行业资讯] 吹瓶机吹瓶过程中常见问题

2020-06-09

-

-

[行业资讯] 两步法吹瓶工艺原理分析及解决方法

2020-06-09

-

-

[行业资讯] 吹瓶机行业面临洗牌,这些厂家将淘汰?

2020-06-09

-

-

[行业资讯] 多种全自动吹瓶机的共同特点

2020-06-09

-

-

[行业资讯] 吹瓶机和吹塑机的区别?吹瓶和吹塑工艺的区别?

2020-06-09

-

-

[公司新闻] 中国制造网认证供应商证书

2020-06-09

0576-88229188

0576-88229188

0576-88229188

0576-88229188